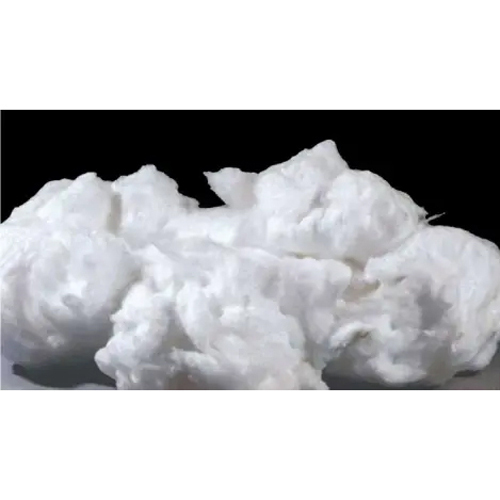

Sectional Pipe Insulation

80.0 INR/Kilograms

Product Details:

- Feature Durable

- Surface Treatment Coated

- Size Len. 1000mm

- Material Rockwool

- Thickness 25-100 Millimeter (mm)

- Usage & Applications Acoustic Insulation

- Click to View more

X

Sectional Pipe Insulation Price And Quantity

- 100 Meter

- 80.0 INR/Kilograms

Sectional Pipe Insulation Product Specifications

- Len. 1000mm

- Durable

- Rockwool

- Coated

- 25-100 Millimeter (mm)

- Acoustic Insulation

Sectional Pipe Insulation Trade Information

- 5000 Meter Per Month

- 2-10 Days

- Yes

- Free samples are available

- All India

Product Description

Polybond Preformed Sectional Pipe Insulation is a value added product manufactured with chemically coated mineral fibers in specified sizes conforms to IS9842 ASTM C 547 and equivalent BS39584 The prefabricated Pipe Sections are designed for thermoacoustic insulation and fire protection of pipe lines operating at temperatures up to 750 C Polybond Rockwool Pipe Sections are noncombustible easy to cut fit handle and has high levels of thermal efficiency and strength Each section is split and hinged for easy snapon application

Designed for tough thermal and acoustic insulation pipe works its combination of density strength and excellent thermal conductivity at high temperatures offer efficient insulation Preformed Pipe Sections are highly recommended for industrial steam and process pipe lines in oil refineries chemical plants and power projects

Preformed Pipe Sections are highly recommended for industrial steam and process pipe lines in oil refineries chemical plants and power projects

Specification

|

Length |

up to 10 feet |

|

Thickness |

25-100 mm |

|

Brand |

Polybond |

Superior Acoustic Insulation

Utilizing high-grade Rockwool, these sectional pipe insulations provide effective noise reduction for piping systems. The materials natural structure absorbs sound, making them invaluable in environments where noise control is crucial, such as industrial and commercial buildings.

Durable & Protected Surface

Each pipe insulation section is coated for added protection. This surface treatment increases resilience against wear and environmental factors, resulting in longer service life and dependable performance in challenging conditions.

Versatile Thickness Options

Available in thicknesses from 25 to 100 millimeters, these insulation sections offer flexible solutions for different piping diameters and insulation needs. This versatility ensures optimal energy efficiency and sound attenuation for a range of applications.

FAQs of Sectional Pipe Insulation:

Q: How is sectional pipe insulation installed?

A: Sectional pipe insulation is typically installed by securing pre-formed Rockwool sections around the pipe, aligning the 1000mm length pieces, and sealing joints as required. The coated surface aids easy handling during installation.Q: What benefits does Rockwool provide for pipe insulation?

A: Rockwool offers excellent acoustic insulation, fire resistance, and thermal protection. It reduces noise transmission and minimizes heat loss, thereby improving system efficiency and safety.Q: When should I consider using sectional pipe insulation with a coated surface?

A: Coated pipe insulation is recommended for environments that demand added durability, resistance to wear, and protection against moisture or mechanical impact. It is ideal for both industrial and commercial settings.Q: Where can these pipe insulations be applied?

A: Sectional Rockwool pipe insulation is suitable for buildings, factories, and plantsparticularly in areas needing enhanced acoustic insulation on piping systems. Available with distributors, exporters, manufacturers, suppliers, and traders throughout India.Q: What is the process for selecting the appropriate insulation thickness?

A: Choosing the right insulation thickness depends on pipe diameter, required acoustic and thermal performance, and environmental conditions. Usually, thicker sections provide greater insulation; consultation with a supplier can help determine optimal thickness for your scenario.Q: How does acoustic insulation improve working environments?

A: By significantly dampening noise from piping systems, acoustic insulation fosters quieter, more comfortable workplaces and reduces sound disturbances in adjacent spaces.Tell us about your requirement

Price:

Quantity

Select Unit

- 50

- 100

- 200

- 250

- 500

- 1000+

Additional detail

Mobile number

Email

Bhilai, Chhattisgarh, India

Bhilai, Chhattisgarh, India

Call Me Free

Call Me Free

English

English Spanish

Spanish French

French German

German Italian

Italian Chinese (Simplified)

Chinese (Simplified) Japanese

Japanese Korean

Korean Arabic

Arabic Portuguese

Portuguese